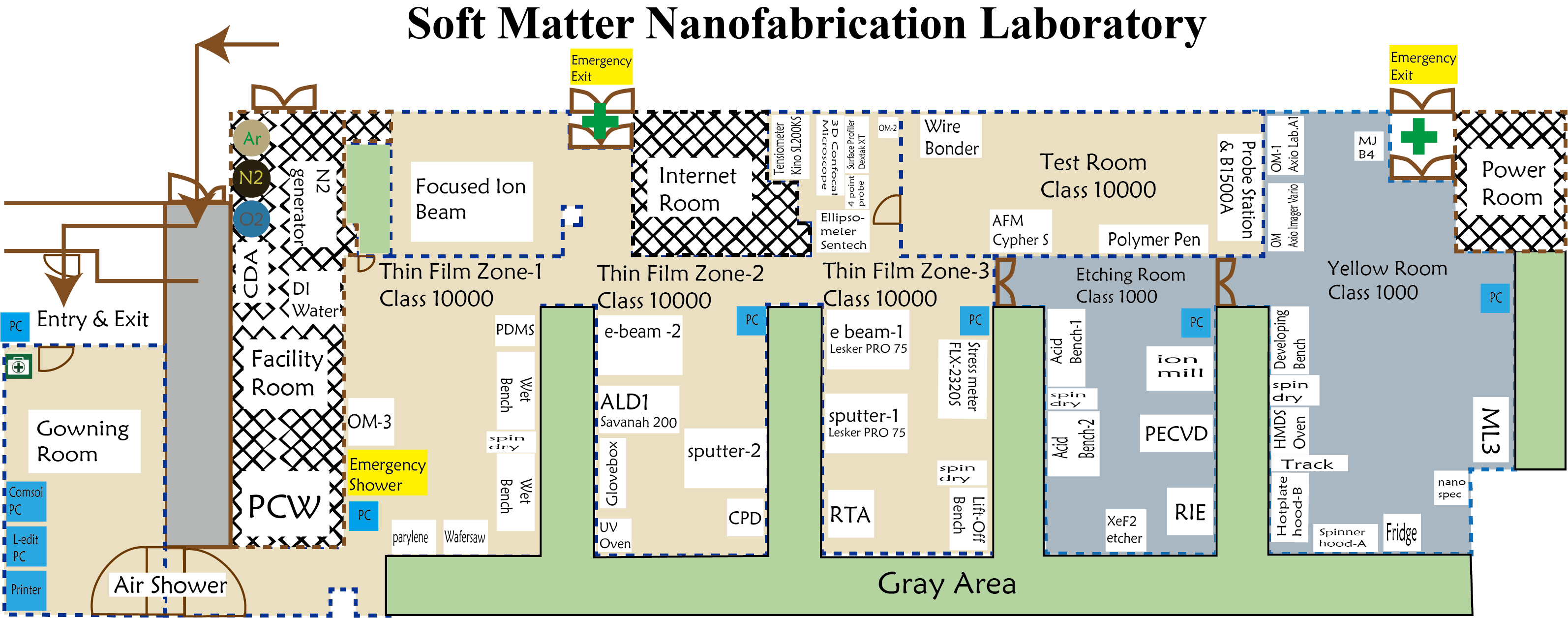

软纳米平台(Soft Matter Nanofab;SMN)是专门为了研发软物质、将新型材料的各种优异性质器件化并且实用化,而创建的一个微纳加工共享平台;本平台全名为:软物质微纳加工实验室(Soft Matter Nanofabrication Laboratory)。本平台净化室位于物质科学与技术学院(物质学院)7号楼一层南侧,实验室性质为电子厂房洁净室,包含千级和万级两个洁净区域,共占地650平方米;本平台为小规模、高水平微纳加工实验室,主要提供光刻、蚀刻、薄膜、和器件封装/测试等工艺,能够为软物质的研究,提供先进且全面的器件制备能力。

软纳米平台的建设构想由物质学院创建院长,杨培东院士提出,软物质是介于固态和流体之间的物质,主要三大特性为具介观结构,受扰动易形变以及结构上能够自组装。未来软物质在生物领域、能源领域以及固态量子领域将扮演重要角色,因此需要依赖微纳加工技术推进软物质科学发展。软纳米平台要突破传统微纳加工的工艺限制,为不同软物质的器件开发研究,提供最先进的微纳加工能力;软纳米平台不但是物质学院三大科研支撑平台之一,也是上海科技大学目前所创建的数个重点资源平台的其中之一。软纳米平台由上海市政府提供建设经费,在上海科技大学相关部门的合作及指导下,由物质学院负责平台规划、筹建、以及运行等相关工作。作为一个大型设备共享的校级平台,本平台不仅对校内全面开放,更将作为校内外合作和业界产品开发的公开交流平台,以实现上海科技大学强调的“推进科技进步、驱动产业发展”创新价值与理念。软纳米平台将致力成为一个集学、研、制、测一体化的科研平台,并作为上海科技大学的科研保障基地之一。

目前, 软纳米平台团队为本校2门微纳加工课程的教学团队成员。(1) 秋学期课程名称:软物质微纳加工(含实验),课程号:MSE2108,为本科/研究生合一课程,6学分中3学分为实验课,即每周9个实验课学时,学生将学习并获得32套微纳加工设备的权限,可自主操作设备来制备课程器件。 (2) 春期课程名称:微纳加工基础与实验 , 课程号:MSE1719,为本科生课程,3学分中2学分为实验课,即每周6个实验课学时,学生将学习并获得16套微纳加工设备的权限,可自主操作设备来制备课程器件。软纳米平台团队负责设备教材,培训和考核。

About Us

Soft Matter Nanofabrication Laboratory, as we would abbreviate it as Soft Matter Nanofab (SMN), is one of major shared platforms at ShanghaiTech University. This platform was initiated in 2017 and the aim is to accelerate the research and development for soft matters and their device-level applications. Soft Matter Nanofab is located in the south side of the 1ST floor in the Building #7, of the School of Physical Science and Technology (SPST). It is a clean room for microelectronics manufacturing, and the clean room area is ~650 squire meters consisting of Class 1,000 and Class 10,000 areas, specifically. Soft Matter Nanofab considers itself as a small-scale yet high-standard platform, serving its users with state-of-the-art tools of lithography, etching, thin film growth, and packaging/testing. Our micro/nanofabrication tools are specifically for bolstering research regarding rising soft matters with potentials for future applications.

The initial blueprint of Soft Matter Nanofab was originally depicted by SPST Founding Dean, Prof. Peidong Yang. Mainly, Soft Matter Nanofab will provide state-of-the-art micro/nanofabrication capabilities to promote next-generation devices using soft matters for applications specifically in energy, biology, and quantum electronics. Soft Matter Nanofab is one of the three SPST research centers; meanwhile, it is also one of key shared instrumental platforms for teaching and research at ShanghaiTech. With the financial support from Shanghai Municipal People’s Government, and with synergistic efforts of ShanghaiTech’s administrative offices, SPST is in charge of founding SMN as well as operating SMN. Being a major platform at a university-level, Soft Matter Nanofab is not only open to users across the campus, but also to external researchers. By sharing complete capabilities in device research, Soft Matter Nanofab encourages both academic and industrial collaborations for soft matter research on it's pathway towards real-world applications. Soft Matter Nanofab will devote it's future efforts to integrate functionalities in teaching/learning, research, as well as technology development, in order to serve as a top-notch platform at ShanghaiTech.

SMN staff are members of two levels of ShanghaiTech micro/nanofabrication course developing and teaching team. Course MSE 2108: Nanofabrication for soft matters (lectures and experiments) is available for graduate and undergraduate students. It has 6 credits, including 3 credits for experiments. In 9 course hours per week, students will gradually learn 32 tools and get qualified to use them. The goal is to allow students to independently operate and integrate tool functions for fabricating selected complex devices. Course MSE 1719: Manofabrication basics and experiments is only available for undergraduate students. It has 3 credits, including 2 credits for experiments. In 6 course hours per week, students will gradually learn 16 tools and get qualified to use them. The goal is to allow students to independently operate and integrate tool functions for fabricating selected simple devices.